Weser Stahl, a steel company based in Stuhr-Brinkum in Lower Saxony in Germany, is relying on comprehensive automation to meet the increasing challenges from international competitors. The key element of its in-house logistics system is a combined storage-sawing-robot system supplied by KASTO. Recently installed, it provides a completely unmanned material flow, from storage of the raw material to provision of the sawn sections for shipment. For Weser Stahl this means greater efficiency, higher productivity and more ergonomic working conditions.

Steel is one of the most frequently used materials in industry. Examples are power generation, automotive manufacturing, food production and construction. It is also applied in many different ways and different forms because, as we know, steel is not just steel. Today more than 2,500 standard grades of steel are in use throughout the world, from simple construction steel to special high-quality alloys. These, in turn, are available in a wide range of dimensions and geometries. All of these factors make the steel trade very challenging. Companies that want to succeed in the increasingly competitive international environment must be able to supply their customers at all times with the materials they need, cut to their requirements.

This situation is all too familiar to Weser Stahl. Based in Stuhr-Brinkum near Bremen, the company has specialised for many years in the sale of hot-rolled and forged steel bars, steel tubes and bright steel. It is part of Westfälische Stahlgesellschaft, an owner-managed group of companies with four locations in Germany. Steel distribution, production of bright steel and material testing are combined here under one roof. Weser Stahl delivers mainly to customers in northern Germany and Scandinavia. The group as a whole sells some 250,000 tonnes of material each year, and Weser Stahl accounts for about 30,000 tonnes.

Increasing numbers of orders and declining batch sizes

A large percentage of the company’s products are partially finished. More than half of the items shipped from the storage and production facilities in Stuhr have already been cut to size. The figure is rising, as Dr. Markus Krummenerl, Managing Director of Weser Stahl, points out: “Our customers are outsourcing more and more machining steps in order to save capacity. For this reason we’ve been continually expanding our portfolio in this area in order to fulfil as many of their wishes as possible.” But this has also led to increasing customisation: “Our order numbers have been rising, while batch sizes have been shrinking. This of course poses a big challenge to us in manufacturing and logistics.”

Weser Stahl relies on state-of-the-art machinery and equipment to meet this challenge. It has a number of band saws and circular saws for cutting various materials to size. These have been supplied for many years by KASTO, a group of companies based in the southern German town of Achern and known for its high-quality, high-performance machines. “We appreciate KASTO’s ability to provide solutions even when we have special requirements,” says Krummenerl. This is why Weser Stahl also turned to the saw and storage equipment manufacturer when it decided to launch another ambitious project.

Unattended operation reduces the burden on employees

The goal was to automate the provisioning of the saws so that they could run largely unattended, enabling Weser Stahl to handle the increasing numbers of orders and meet the growing customer demand for partially finished products. “Another important aspect for us was work safety,” adds Krummenerl. “We wanted to make our employees’ work environment more ergonomic and their daily tasks easier, in this way preventing accidents and injuries.” Previously, material had been conveyed to the saws by an indoor crane – a laborious and not entirely hazard-free process involving bars and tubes weighing a tonne or more. “We therefore went to KASTO and asked them to suggest some solutions.”

After detailed calculations, KASTO determined that a fully automatic cantilever arm storage system would be best in this case. Weser Stahl therefore opted for a KASTOcenter varioplus 4. Measuring almost eight metres in height, the system provides 1,398 storage spaces for material up to seven metres in length. The compartments have a usable loading height of 50 to 430 mm, and each can take a maximum payload of four tonnes. Bar stock is handled by a storage and retrieval machine (SRM) that moves over the storage block at speeds of up to 60 metres per minute. Two KASTOvariospeed circular saws, also fully automatic, and one KASTOtec band saw are connected to the storage facility.

Intelligent warehouse management saves time and cuts down travel

Weser Stahl stores about 20 percent of its inventory in the KASTO system. The selection is governed by experience, explains Sales Manager Stieven Harder: “We know what kinds of pre-cut parts are often requested, and we give preference in storage to these materials.” Bar stock is usually delivered by truck in bundles, after which it is unloaded and placed in storage using a transport cart. Selection of a suitable storage compartment is handled by the KASTOlogic warehouse management system, which optimises times and travel for the SRM and thus keeps access times to a minimum. “In addition, as protection against rust we have separate storage areas for bright steel and rolled steel,” Harder continues. “The rules for this are contained in the software.” KASTOlogic is also connected via a special interface to Weser Stahl’s higher-level ERP system. This ensures greater transparency and simplifies the transmission of order data.

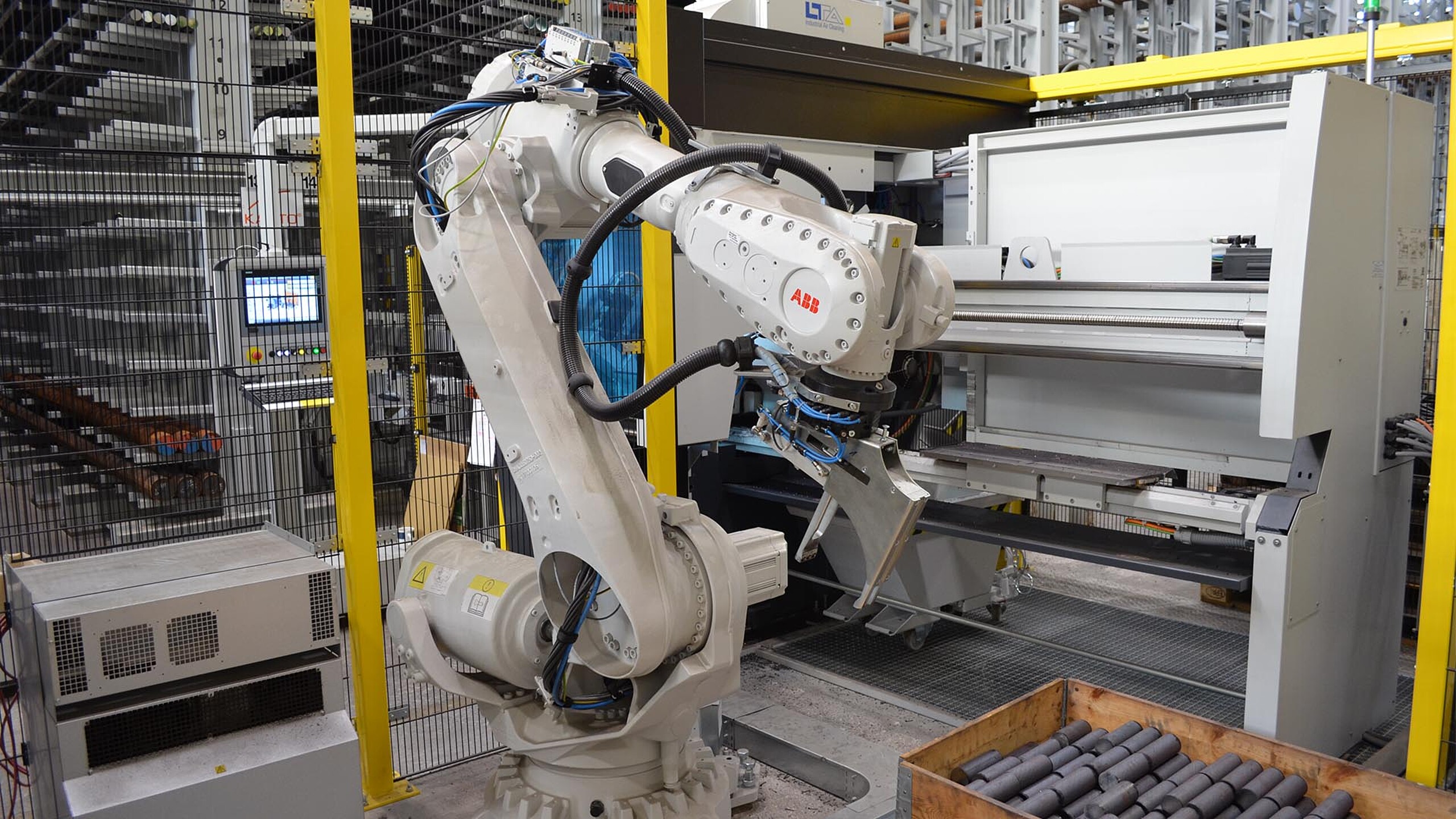

Material removed from storage is conveyed via roller tracks to the saw in question. A handover station in front of the saw serves as an additional buffer to avoid waiting times. The two KASTOvariospeed circular saws each have a cutting range of up to 150 mm; the KASTOtec FC 4 band saw is suitable for larger material up to 430 mm in diameter. “This saw was in use even before the storage system was built,” says Harder. “KASTO simply integrated it into the new system and installed the two circular saws as well.” Weser Stahl also relies on automation for the removal of material. The KASTOtec saw is equipped with a plate-turning and stacking system, and the two KASTOvariospeed saws each have an industrial robot that automatically removes sawn sections and stacks them on pallets as required for each order. The automated peripheral systems, including robot integration, also come from KASTO. Mechanically, electrically and in terms of software they are perfectly matched to the automatic sawing machines and storage system. “In this way we’ve created a continuous material flow that can function fully unattended if necessary – and around the clock,” says Harder. “The result is an enormous increase in efficiency and performance, as well as more ergonomic working conditions for our employees.”

One-of-a-kind SRM

Remnants are returned to storage by the conveyer system and the SRM. The latter is specially modified so that it can carry not just one bar, but several at the same time. “The standard version couldn’t do this, but KASTO reconfigured it to meet our requirements.” says Stieven Harder. “There’s nothing else like it in the world.” Dr. Markus Krummenerl adds: “This is a good example of how well KASTO can respond to the special needs of its customers. Whether it’s custom-manufactured equipment or service after commissioning, we know we’re in good hands.”

Weser Stahl and KASTO have even more plans for automation. Together with the company Jungheinrich they are currently planning to connect the saws to a driverless transport system that removes pallets with stacked cut parts from the working area of the KASTOsort robot and takes them to the dispatch warehouse. “KASTO has already created the necessary peripheral equipment,” says Harder. “For example, the protective enclosures of the saws each have a roller gate and optical sensors for trouble-free entry and exit by the driverless transport system.” The companies are also cooperating closely in software engineering to ensure smooth interaction of all the components. “In addition, we and KASTO are planning a warehouse for our location in Plettenberg,” says Krummenerl. “We’re glad to have a partner that can provide both reliable equipment and fresh ideas.”