KASTO at LogiMAT

Automating Storage, Optimising Efficiency

Automated storage systems enable fast, precise storage and retrieval, save space, minimise errors, and reduce labour costs. At LogiMAT (11 to 13 March, Stuttgart), storage and sawing specialist KASTO will once again demonstrate in Hall 3 at Stand 3F44 how companies can optimise their material flows with well-thought-out solutions.

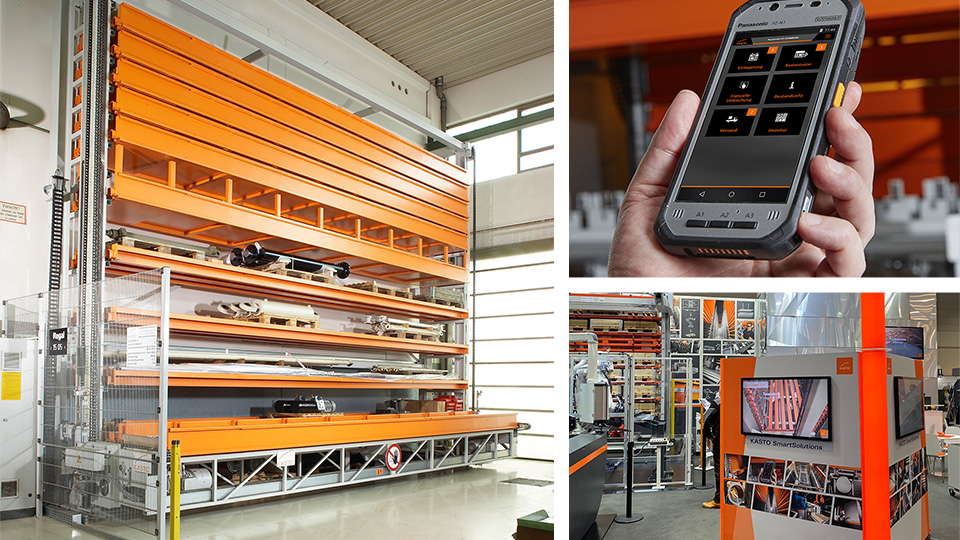

With a small footprint, high efficiency, and short travel distances, tower storage systems offer numerous advantages. By using vertical storage, users require only a few square metres of floor space relative to capacity – a major benefit, particularly in confined production facilities. Tower storage solutions such as KASTOecostore or UNITOWER can be seamlessly integrated as buffer storage within production halls. They are equally impressive when distributors need to stock smaller quantities of bar stock and sheet metal. Thanks to automation, users can access items quickly, while the enclosed system protects goods from dust, theft, and damage.

At the exhibition stand, KASTO will showcase how the modular compact cassette storage system UNITOWER optimises material flow. The storage system is suitable for flat and long material as well as pallets, with easy-to-implement custom adaptations. Its standout feature: low-maintenance precision roller chains ensure minimal upkeep costs.

Multiple Insights

The SmartSolutions Corner at the stand will highlight the extensive application possibilities for KASTO systems in storage, sawing, and material handling. Here, the specialist will demonstrate its expertise in storing and processing semi-finished products.

With KASTOlogic mobile, warehouse processes can be intuitively controlled via an app – a decisive advantage for modern, digital working environments. Its user-friendly interface allows real-time monitoring and control of material movements and inventory, providing a clear overview. KASTOflow solutions optimise the entire material flow by efficiently managing the interface between storage and production processes. Additionally, under the name KASTOfenestra, KASTO will present specialised solutions for window construction, including the brand-new cassette quick-change station that enables fast and user-friendly order picking of profiles.

Furthermore, KASTO will showcase the UNITOWER cnc, specifically designed for manufacturing companies looking to integrate material provisioning directly with CNC machines.

Seeing is Believing

KASTO invites all interested visitors to join organised visits to reference customers around Stuttgart during the trade fair. This will provide valuable insights into the real-world application of KASTO’s products and technologies. Visitors will learn first-hand about challenges KASTO has successfully solved. “Customers can get a much better understanding of our solutions than at the exhibition stand alone,” emphasises Armin Stolzer, Managing Director. Those wishing to secure a spot can register via sales@kasto.com.

Beyond LogiMAT, there is always the opportunity to visit KASTO’s headquarters in Achern-Gamshurst, Baden. In a large showroom, KASTO presents its innovative solutions and answers all questions related to storage and sawing.

KASTO at LogiMAT: Hall 3, Booth 3F44