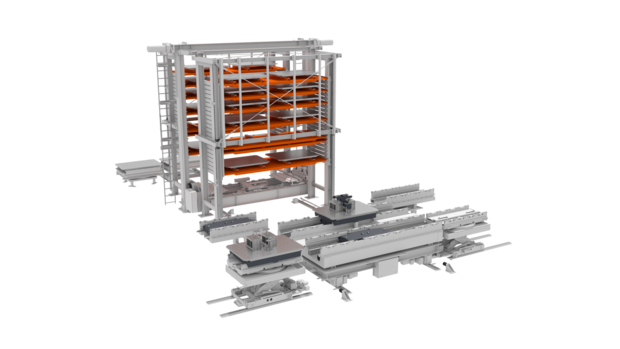

UNITOWER cnc

| Type: | Buffer Storage |

|---|---|

| Storage Type: | Tower system |

| Loading per storage: | 1 t - 5 t / 2200 lbs - 11000 lbs |

| Storage length: | 2 m - 4 m / 7 ft - 13 ft |

| Storage size: | 10 - 90 Locations |

| Rack support: | Yes |

| Integrated saw possible: | Yes |

Buffer storage for automatic loading of CNC machines

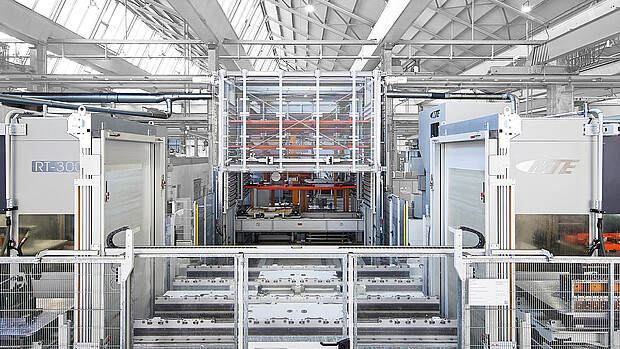

The system significantly improves productivity by continuously supplying CNC machining centres and milling machines with loaded pallets that employees prepare at separate workstations. The storage tower is loaded during machine operation. There are no expensive downtimes, and the entire system, including capital-intensive machinery, can run unmanned for long periods, for example at night.

Users can connect several processing machines - regardless of the manufacturer - to a tower storage system. The UNITOWER cnc can be connected fully automatically to several set-up and machine transfer stations via transfer units and roller conveyors. The storage and retrieval unit (SRU) transfers the machine pallet equipped with fixtures and workpieces to a transfer carriage. This automatically moves it to the location specified by the control system. Partially and fully machined pallets with fixtures and workpieces can also be temporarily stored or returned in the same way.

The UNITOWER cnc is managed by KASTO's own warehouse management and production control software, KASTOlogic. It ensures that the required workpieces are provided at the corresponding CNC machine for each order, checks the availability of all necessary NC programs and tools, monitors the production processes, calculates completion dates and coordinates the order sequence in a time-optimised manner. Faults can be rectified quickly and easily via remote maintenance - ensuring reliable operation of the entire system.

The UNITOWER cnc also scores highly in terms of ergonomics, as the manual handling of workpieces, some of which weigh several tonnes, is reduced to a minimum. This is good for employees' health and also frees up time for other tasks. Thanks to its modular design, the storage system can be expanded almost at will - a big plus for growing companies.

Your benefits at a glance

- Supplies the machines continuously with ready-prepared pallets, which employees can prepare in parallel at separate workstations with fixtures and workpieces

- The tower machine can be loaded parallel to production during machine runtime

- Several processing machines can be integrated, regardless of the manufacturer

- Maximum storage space with minimum floor space

- With the help of the KASTOlogic warehouse management software, the required workpieces are made available at the corresponding CNC machine on an order-related basis, the availability of all necessary NC programs and tools is checked, the production processes are monitored, completion dates are calculated and the order sequence is coordinated in a time-optimised manner

- Thanks to its modular design, the storage system can be expanded almost at will.

- The UNITOWER cnc is ergonomically impressive, as the manual handling of workpieces, some of which weigh several tonnes, is reduced to a minimum