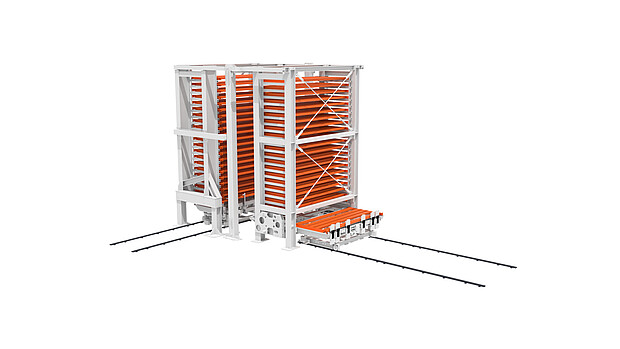

UNITOWER B

| Type: | Sheet metal storage |

|---|---|

| Storage Type: | Tower system |

| Loading per storage: | 1 t - 5 t / 2200 lbs - 11000 lbs |

| Storage length: | 2 m - 8 m / 7 ft - 26 ft |

| Storage size: | 10 - 100 Locations |

| Rack support: | Yes |

| Integrated saw possible: | Yes |

High volume with a little space

The UNITOWER for sheet metal is optimised for the requirements of sheet metal processing and can be used flexibly for different loading heights.

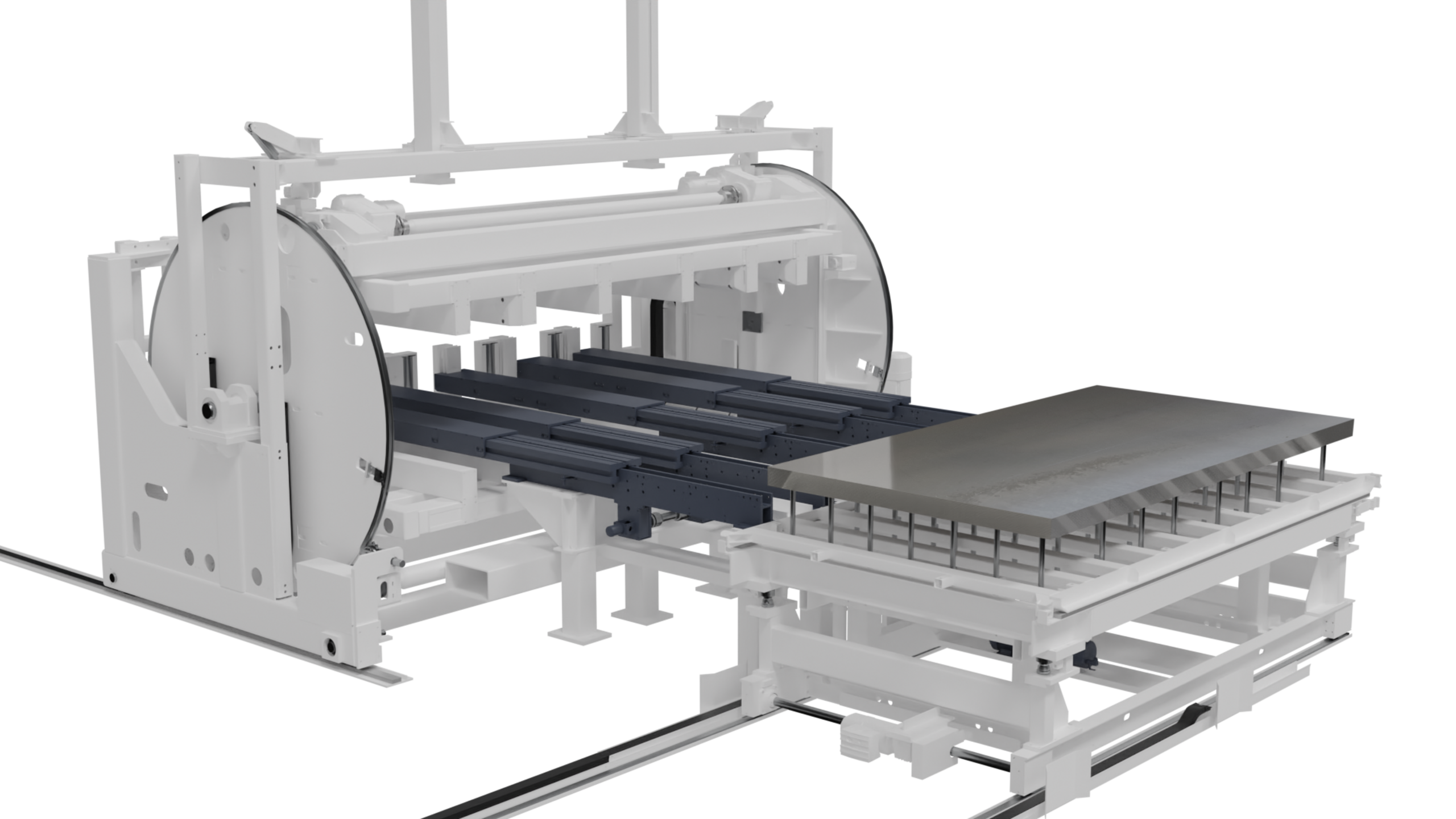

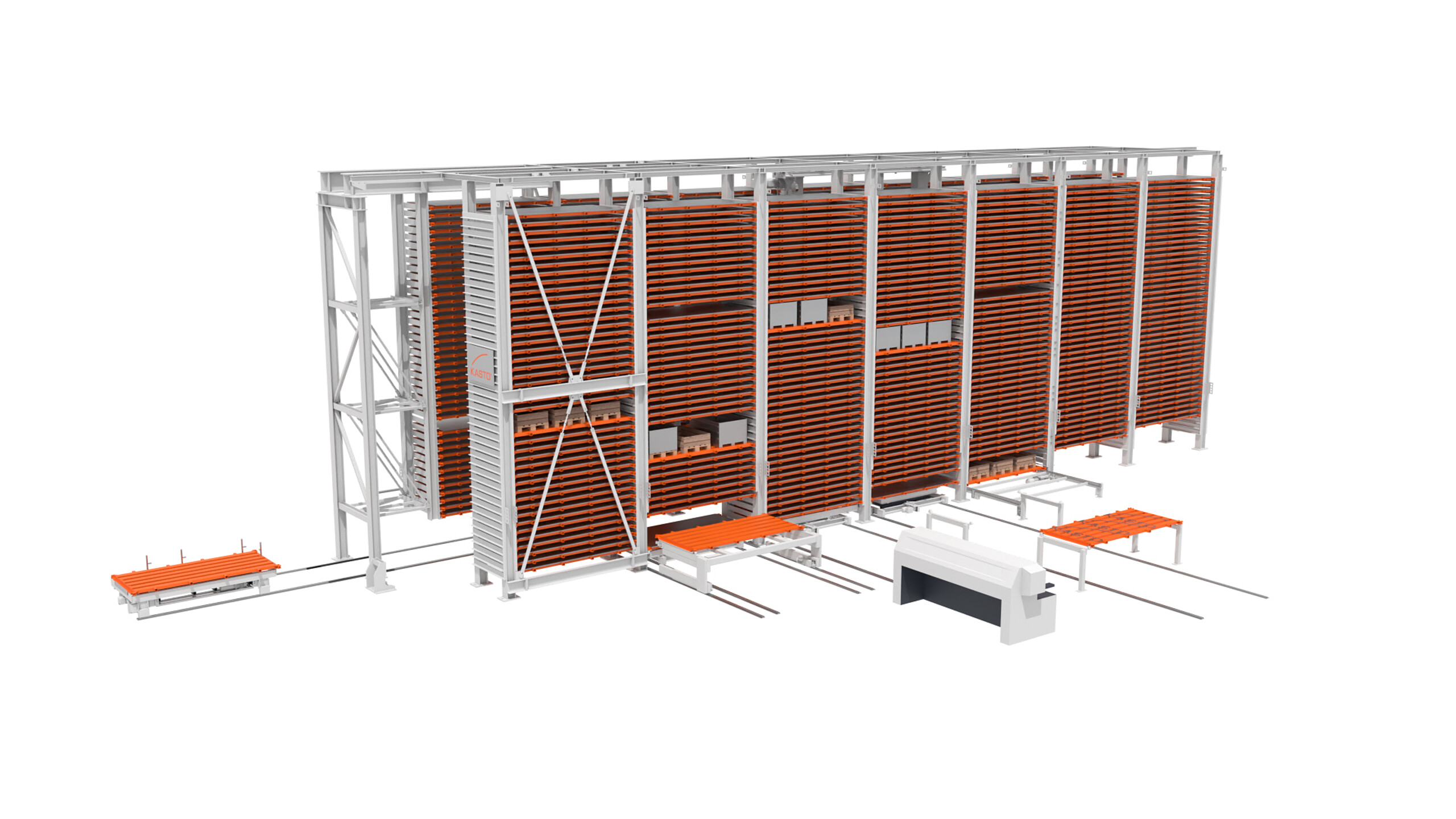

The stations can be customised according to your processes to ensure efficient material logistics and are available for all storage sides. The storage station can be supplemented with a storage rack for free-lifting the goods to be loaded. Unpacking tables are also available. The connection or integration of sheet metal processing machines is also possible.

Various options are available for the UNITOWER, such as integrated weighing devices, turning devices or lift-out stamps, which you can read about in detail in our brochure.

Your benefits at a glance

- As a buffer store in production or for small storage quantities

- Easy to use and quick to set up for loads of up to 5 t per cassette

- Various loading heights are possible

- Significant area gain through building cladding and pit solution

- Low maintenance and high reliability

- The UNITOWER can be connected to a saw via roller conveyors

Downloads

Technical Data

| Loading per storage space | 1 - 5 t | 2200 - 11000 lbs |

| Economic storage size | 10 - 100 storage locations | 10 - 100 storage locations |

| Storage lengths | 2 - 8 m | 7 - 26 ft |

| Economic system height | 4 - 24 m | 13 - 79 ft |

| Self-supporting construction possible | yes | yes |

| Number of accesses per hour (per OGC) | 1 - 30 | 1 - 30 |

| Semi-integrated sawing machines possible | yes | yes |

| Fully integrated sawing machines possible | with limitations | with limitations |