KASTOpick bar

| Product group: | Storage, Saw |

|---|---|

| Material shape: | Bar |

| Product type: | Robotics, Infeed, Commissioning |

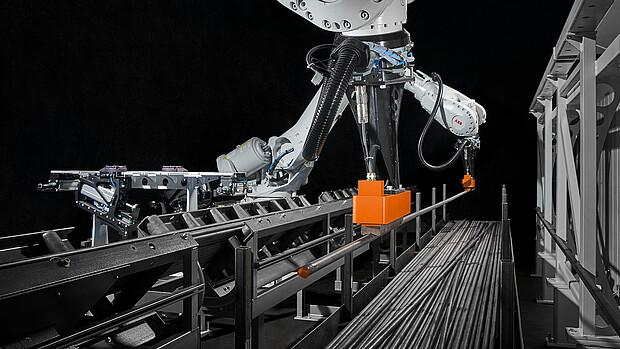

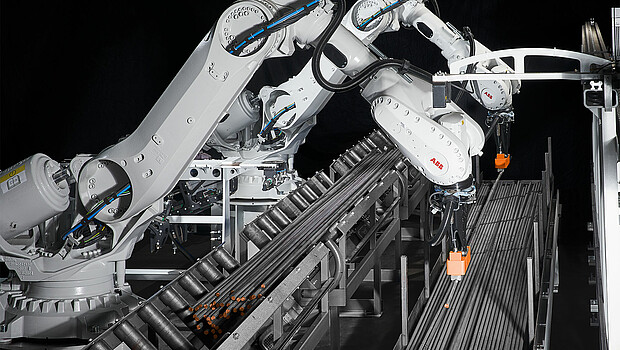

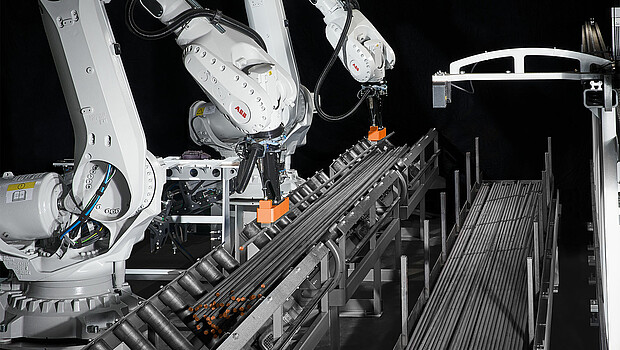

Automated bar separation from storage cassettes

KASTOpick bar is capable of fully automated, unmanned removal and manipulation of bar stock from storage cassettes. This allows subsequent processing machines to be loaded or optimised consignments to be formed for strapping. The separating system can be connected to new storage solutions as well as to existing systems that store magnetic blank and black material. A bar weight of up to 500 kg is realised as standard, but higher individual bar weights are also possible on request. For complete process automation in the steel trade or in steel processing, KASTOpick bar acts as a link between the storage system and saws or strapping units.

The versatility of the KASTOpick bar gripper systems enables a wide range of profiles to be separated: flat, square, hexagonal and round material as well as round tubes and profile tubes that are not wrapped or labelled. The robot system obtains all the information required for safe removal and transport by communicating with the ERP system or the upstream or downstream machines. The stacking pattern of the bars is automatically optimised based on the dimensions of the material and the order volume.

Removal process

The removal process begins with a scan by the 3D sensor measuring head, which is moved over the cassette. The resulting 3D point cloud is processed using an algorithm developed by KASTO. All possible gripping points are analysed for each bar within the 3D image and each robot. At the same time, the system checks for collisions with other system components.

If a collision-free gripping point is found for a rod and both robots, the robots predict the planned movement. Collision-free gripping points are determined from the point cloud and the algorithm generates a movement path, removes the rod and transports it to the target position. The process then starts again.

Your advantages at a glance

- Automated picking of material bundles and order preparation for the steel trade

- Enables fully automated and unmanned material removal in 3-shift operation

- Interlinking of production steps through the connection of downstream machines

- Optimised and unmanned picking and material provision

- Suitable for a wide variety of materials: flat, square, hexagonal and round material as well as round and profiled tubes

- Increased efficiency through material removal and manipulation

- No programming or teach-in required by the user

Technical data on request.